The Only Guide for American Plastics

Wiki Article

Our American Plastics Ideas

Table of ContentsThe American Plastics DiariesThe smart Trick of American Plastics That Nobody is Talking AboutThe smart Trick of American Plastics That Nobody is DiscussingAbout American PlasticsAmerican Plastics - An Overview

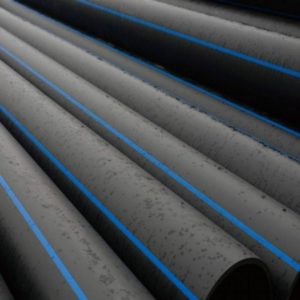

Comprehending these elements will allow you to make educated decisions when selecting one of the most ideal pipe for your project. The product composition of the HDPE pipe plays a crucial duty in establishing its PSI ranking. HDPE pipelines are made from high-density polyethylene, a thermoplastic known for its stamina and resilience.Various grades of HDPE might have differing PSI ratings, so it is important to take into consideration the product composition when picking a pipeline for your particular needs. The diameter of the HDPE pipe is an additional essential variable that influences its PSI score. Larger size pipes typically have greater PSI ratings, as they have much more worldly and area to hold up against pressure.

The wall thickness of an HDPE pipeline likewise impacts its PSI rating. Thicker wall surfaces provide increased toughness and resistance to pressure, permitting the pipe to take care of higher PSI levels. Conversely, pipelines with thinner wall surfaces might have lower PSI rankings and are ideal for applications with lower pressure needs. The temperature at which the HDPE pipe will run is an important factor to consider when determining its PSI score.

It is necessary to consider the maximum operating temperature level of the pipeline and pick a PSI rating that can manage the expected temperature range - https://www.pearltrees.com/americanplastics#item744459246. The PSI rating of HDPE pipelines is identified through extensive screening and certification processes. Comprehending exactly how these ratings are identified will certainly give you with confidence in the accuracy and integrity of the selected pipeline

Little Known Facts About American Plastics.

Organizations such as the American Society for Testing and Products (ASTM) and the International Organization for Standardization (ISO) have developed details tests to assess the efficiency and strength of HDPE pipelines. These examinations action aspects such as burst stress, tensile strength, and long-lasting hydrostatic toughness to determine the suitable PSI rating.The stress at which the pipeline bursts establishes its maximum PSI score, indicating the stress it can withstand without failure. Long-term hydrostatic strength testing reviews the pipeline's capacity to endure stress over a prolonged duration.

HDPE pipelines with higher PSI ratings are naturally a lot more durable and immune to deformation under pressure. high quality hdpe pipe. Choosing pipelines with greater ratings guarantees they can withstand unforeseen pressure surges or external loads, minimizing the threat of pipeline failure and the demand for frequent replacements. HDPE pipes with higher PSI rankings typically have enhanced resistance to environmental variables such as UV radiation, chemicals, and abrasion

More About American Plastics

By choosing HDPE pipelines with higher PSI rankings, you can ensure the safety and security of your system and employees. These pipes are developed to deal with high-pressure situations, minimizing the risk of leakages, ruptureds, and various other harmful incidents that can endanger individuals or building. Investing in HDPE pipelines with greater PSI rankings may need a greater upfront price, yet it uses lasting cost savings.

These pipes make sure the secure and reliable circulation of drinkable water from the source to the customer. HDPE pipelines with ideal PSI rankings are commonly used in gas circulation networks. They can securely deliver all-natural gas or various other gases from the source to domestic, commercial, and industrial parks, making sure reliable and efficient gas supply.

Excitement About American Plastics

They can handle the pressure required for efficient watering and watering of grass, yards, parks, and sports areas (hdpe pipe suppliers Midland TX). HDPE pipes with high PSI rankings are excellent for delivering different industrial chemicals. They can deal with the pressure demands and resist chemical deterioration, ensuring the safe and efficient transportation of chemicals in commercial settings

Proper installment is critical to make best use of the performance and long life of HDPE pipes. Follow these guidelines when setting up HDPE pipelines with specific PSI scores.

Choose the ideal jointing approach based on the PSI score of the HDPE pipeline. hdpe pipe in stock Midland TX. Common jointing techniques include butt blend, electrofusion, and mechanical combinings. Adhere to producer guidelines and make sure proper positioning and welding for a protected and leak-free joint. Select installations and accessories that look what i found are compatible with the PSI score of the HDPE pipeline.

American Plastics Can Be Fun For Everyone

After setup, perform pressure screening to guarantee the integrity of the HDPE pipe system. Adhere to sector requirements and standards to conduct the proper pressure tests, such as hydrostatic or pneumatically-driven testing, to validate the system's capacity to take care of the required pressure. Appropriate backfilling and compaction around the set up HDPE pipelines are vital to provide stability and secure the pipelines from exterior loads.Report this wiki page